ZHANGJIAGANG FLAME MACHINERY CO.,LTD.

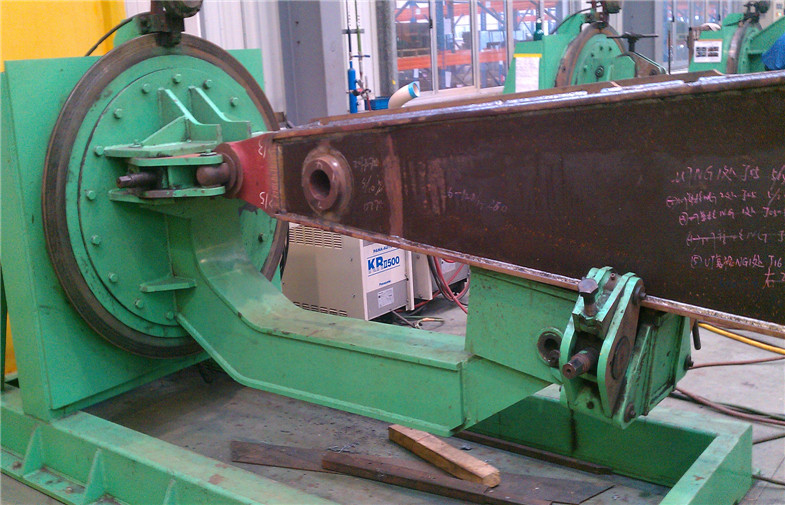

Weldsuccess product designs combine accuracy, speed, flexibility,

durability, reliability and advanced technology to deliver machines

with the highest performance-to-price ratio in the industry with CE

certificates.

Weldsuccess attend the International Fair every year, like the

Germany Essen,USA Fabtech and some other international local

welding fair.

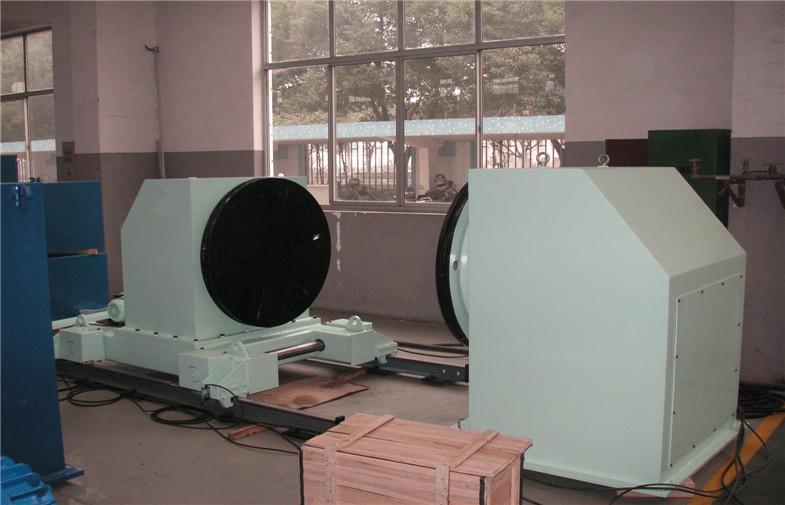

And since 2012, we focuses on the international market only. The

welding positioners, welding rollers and welding column boom have

been exported to more than 40 countries.

We are looking forwards to the cooperation with you soon!